Call 01480 8-9-10-11 | Email Us | Mon-Fri 9am–5pm | Customer Login | Vacancies | Videos

Call 01480 8-9-10-11 | Email Us | Mon-Fri 9am–5pm | Customer Login | Vacancies | Videos

BL1500 EV Battery / Table lift with twin-plane automatic titling

Perfect for EV batteries, engines and gearboxes!

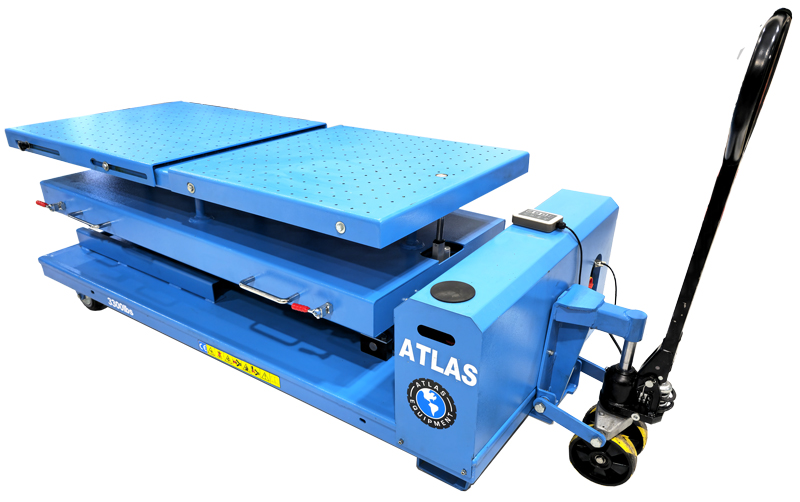

The Hofmann Megaplan BL1500 Electric Battery Lift table provides the ultimate in flexibility for a variety of workshop lifting requirements – engines, gearboxes and now Electric Vehicle batteries. It combines a robust lifting capacity, versatile platform adjustments, and thoughtful design features, making it an adaptable solution for lifting tasks.

Safe access and removal of the vehicle battery is an obvious lifting conundrum being presented to garages with the introduction of EVs. If you are ready to equip your workshop of the future, the BL1500 from Hofmann Megaplan is the perfect solution.

The BL1500, our flagship EV battery/table lift, uses a powerful hydraulic system to lift up to 1500kg and incorporates a twin-plane automatically tilting table top for the ultimate flexibility when positioning and fixing a heavy component under a vehicle. Of course, this versatile lift is not restricted to use with EV batteries, it also provides an ideal solution for other workshop lifting challenges, including engines and gearboxes.

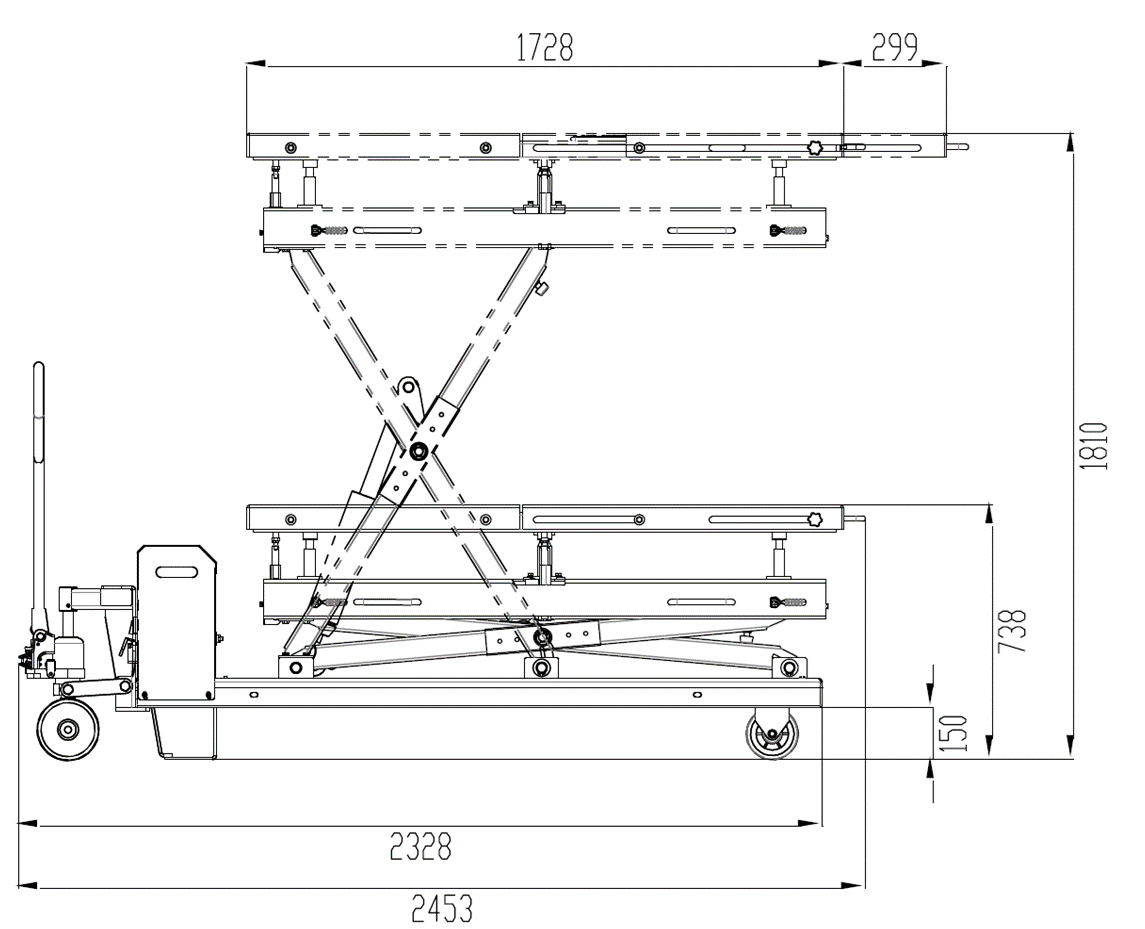

The lift has been specifically designed for the purpose of lifting an electric vehicle battery during maintenance. It can also be used for engine or transmission work. All mechanical frames, including platforms, base frames, and arms, have been constructed using steel plates to ensure a robust and sturdy frame while minimising overall weight. The lift comprises two tables, scissor arms, a base frame, and a mobile jack.

- Powerful hydraulic lift with electric tilting

- 1500kg capacity

- Lifting height 740mm to 1800mm

- Table top: 900mm wide x 1728mm long – extendable to 2027mm

- Twin-plane tilting table top provides the ultimate alignment flexibility with battery/vehicle component

- Tilting angles of +/- 5.1° (left/right) & +/- 2.2° (front/rear)

- Wired remote control for lifting & tilting

- No installation required

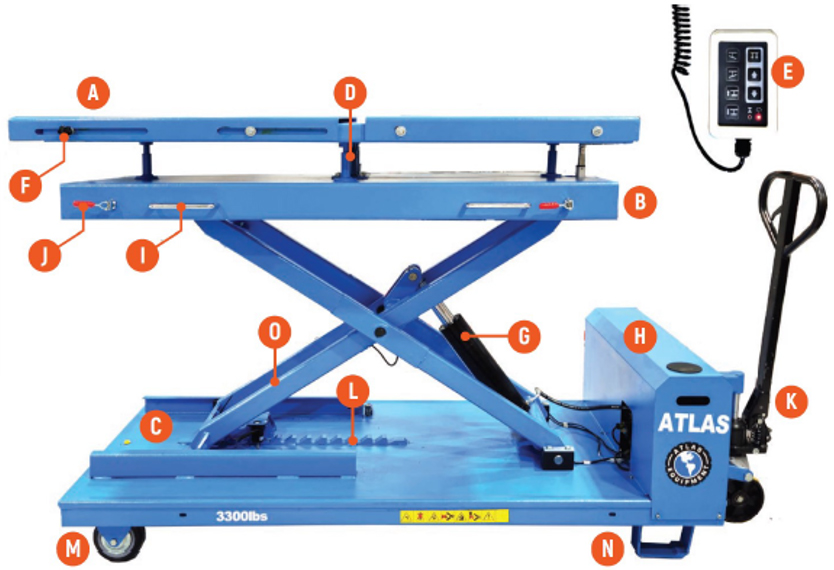

A. Tabletop with multiple threaded locations for accessory attachments

B. Lower table provides support for the upper table.

C. Base frame

D. Linear actuator enables automatic tilting of the top table in both left/right and front/rear directions.

E. Wired control pad controls: power on/off, multi-directional tilting, lift up/down functions

F. Extension of the top table can be achieved by releasing the locking screw

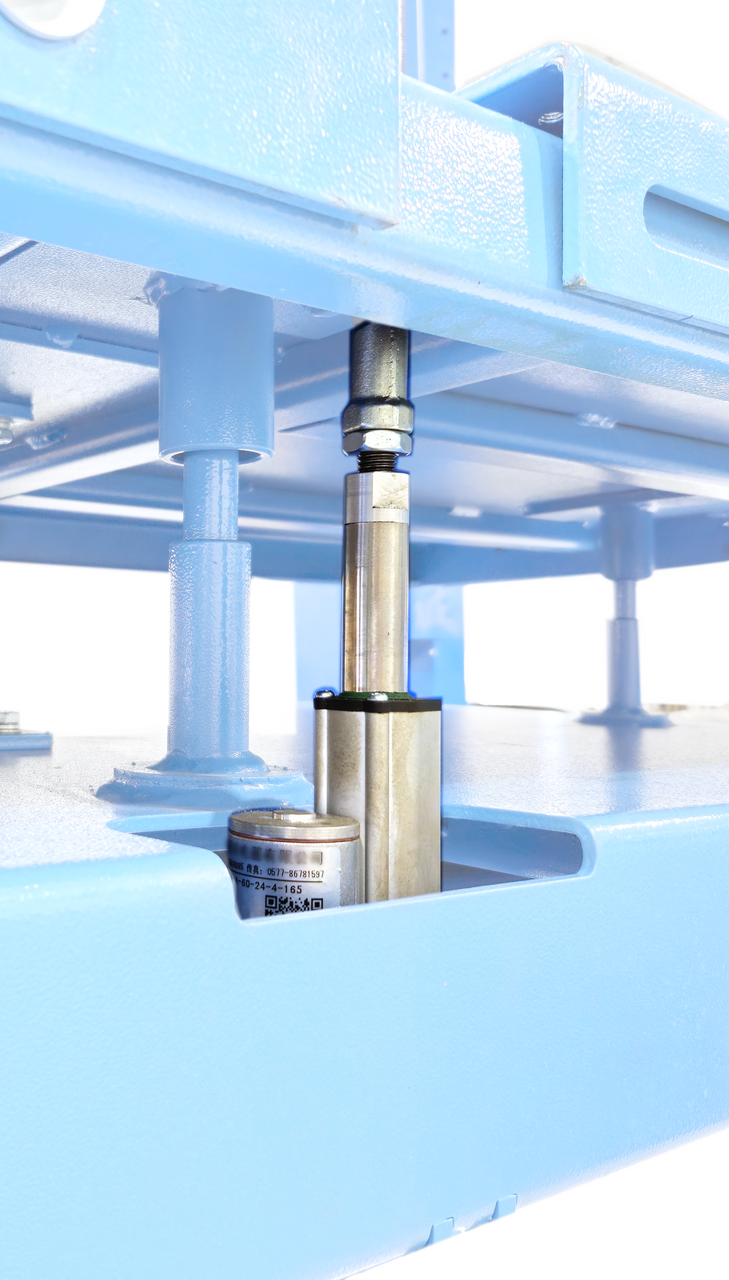

G. Lowering & lifting of the bottom table done by operating the remote control, driven by the hydraulic cylinder

H. Control module unit housing

I. Handles for manual lateral movement; when all locks are release

J. Manual lock release for lateral movements

K. The mobile jack is affixed in front of the base frame to enable the movement of the lift; like a pallet jack

L. Built in safety lock ladder incorporated for added safety

M. Front caster wheels for easy portability

N. Enforced legs allow for stability when in use

O. The bottom table is connected to the base frame through a scissor lifting mechanism

Drivetrain Subframe Assembly Adaptors

An optional (extra cost) seventy piece subframe adapter kit, specifically designed to convert the BL1500 EV lift table into a safe and secure lifting platform, for removing drive train subframe assemblies. Part No: BL1500-TTK